Struggling with rising supply chain costs? You aren’t alone. In today’s complex global economy, the process of managing supply chain expenses is getting harder and harder. But with the right strategies, you can significantly reduce costs and boost your bottom line.

In this guide we’ll share our 6 proven supply chain cost reduction techniques, to help you streamline operations, cut unnecessary expenses, and improve efficiency. You’re in the ideal place to find expert assistance to help you boost your bottom line and turn things around.

Types of Costs in Supply Chain Management

Before we look into the six main supply chain cost reduction techniques, we will first of all delve into the different costs that a firm will come up against, and how they can easily get out of control.

Typically there are five main types of costs in supply chain management, which are:

Investment Costs

In today’s more globalised economy, the majority of supply chains are a multi-site network of manufacturers, suppliers, distributors and retailers that can spread across the world. It is therefore essential to make informed and strategic decisions, such as where to invest in new facilities (such as factories and warehouses) and resources (such as employees and equipment).

Many companies will unfortunately spend too much of their money in the wrong areas at the wrong times, or fail to invest in the right locations at the right times. This can have an extremely negative effect on their financial fortunes.

Transportation Costs

The second type of cost in supply chain management comes in the form of transportation. Typically, the main cause of higher transport costs is inefficient network planning, routing, and deployment of resources.

Procurement Costs

Choosing the right supplier is integral to keeping your procurement costs down. The right supplier will almost always be able to deliver the right products and materials at the right times – and at the lowest price.

Choosing the wrong supplier, on the other hand, could see you dealing with a partner that is both unreliable and too expensive – threatening both your bottom line and potentially your reputation with your customers and clients.

Production Costs

This type of supply chain cost primarily applies to the manufacturing sector. Inflated production costs can be caused by several different factors, such as the inefficient utilisation of certain machines and poor workforce management.

Inventory Costs

The final type of supply chain cost is down to inventory. Businesses across the supply chain spectrum will rely on their inventory to act as a protective buffer against fluctuating supply and demand. While an increased inventory may act as a potential safety net, it is also a large source of costs. Stockpiling can especially cause your warehousing and transportation costs to increase, tying up important capital that could otherwise be spent elsewhere.

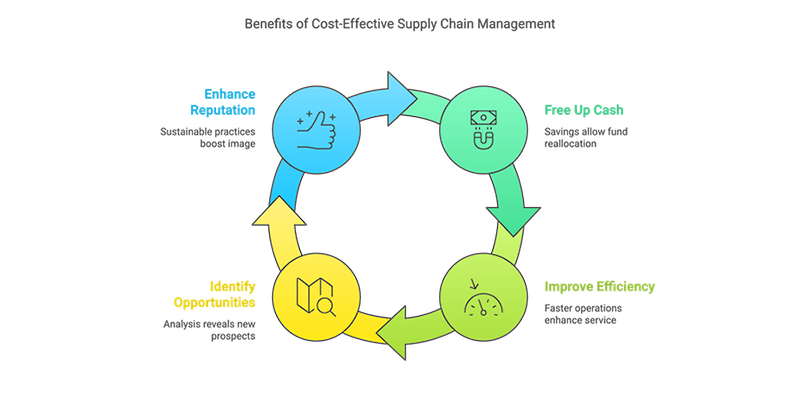

The Benefits of Cost Effective Supply Chain Management

Implementing effective supply chain cost reduction techniques isn’t solely about saving money — it’s also about creating a more efficient and resilient business for the future. By implementing changes like diversifying your supply chain, you can unlock several benefits to your company.

Here are a selection of some of these key benefits:

- Frees Up Cash: By making savings, you are able to redirect funds to other, more critical areas of the business.

- Improves Efficiency: Streamlined processes should lead to faster operations and, in turn, better customer service.

- Identifies Opportunity: Proper supply chain analysis can reveal new, exciting business opportunities.

- Enhances Reputation: Sustainable and efficient practices can go a long way to improving your corporate image.

Supply Chain Cost Reduction Techniques

Now that we have discussed the types of costs companies will face in their supply chains, we can move on to identifying several important supply chain cost reduction techniques that can really help you improve your firm’s financial health. It is important to note that this is not an exhaustive list, and there are many other ways to make savings.

Streamline Ordering Processes

The first of our supply chain cost reduction techniques is to make your ordering processes as efficient as possible. Inefficient ordering processes can lead to wasted time, resources, and money. To optimise this process, consider implementing a single software platform to centralise requisitions and avoid confusion.

Additionally, implementing an approval process, where only designated individuals can sign off on purchases, can further reduce unnecessary spending. You can also consider automating reordering triggers based on inventory levels. This can help maintain optimal stock levels without unnecessary manual intervention.

Manage Inventory

Did you know that inventory costs can account for up to 75% of total supply chain expenses? This makes it an obvious area for cost reduction. One particularly effective strategy is adopting a Just-in-Time (JIT) system of inventory management. This minimises storage costs as well as reduces the risk of overstocking.

Regular reviews of your stock levels and using inventory management software can help you further align your inventory with demand forecasts, as well as assist in identifying slow-moving items.

Monitor Customer Demands

The third of our supply chain cost reduction techniques is to take note of your customers and their demands. By regularly monitoring ordering patterns, you can spot trends that will enable you to identify areas of your current supply chain that need to be tweaked.

For example, you may find that patterns will change from month to month, or season to season, and then use this information to make more data-driven ordering decisions.

Understanding customer behaviour is key to optimising your supply chain. By regularly monitoring ordering patterns, you can spot trends and adjust accordingly. For example, you may notice seasonal fluctuations or changes in product preferences, allowing you to make more data-driven ordering decisions. Leveraging predictive analytics tools can further enhance your ability to forecast demand and plan inventory more accurately.

Make Better Use of Space

As you will no doubt be aware, storing inventory and supplies in a warehouse comes at a cost. Therefore, it’s essential that you look to make the most of your available space. Start out by reorganising your inventory in a way that maximises efficiency — consider using vertical storage solutions or perhaps implementing slotting strategies to store your most high-demand items in easily accessible locations.

Alternatively, if your current warehouse is too large for your needs, why not consider downsizing to a smaller facility? This relatively small change could lead to significant yearly savings.

Track Performance

Likely one of the most overlooked of the supply chain cost reduction techniques, many companies fail to properly track supply chain performance. Doing so can reveal a number of highly valuable insights to assist you moving forwards.

Start off by setting some Key Performance Indicators (KPIs) such as the accuracy of orders, delivery time, and inventory turnover targets. Once these are in place, regularly review performance data using dashboards. This can help you identify areas for improvement.

Periodic audits of your supply chain can also be important in ensuring you meet your goals and are operating as efficiently as possible.

Consider Automation

Automation is no longer a luxury reserved for huge tech companies in Silicon Valley — it’s a necessity in modern supply chain cost reduction techniques. Technologies like Artificial Intelligence (AI) and machine learning can help in optimising various aspects of your chain, including:

- Forecasting consumer demand

- Route planning

- Inventory management

Automation can also have benefits in handling some of the more repetitive tasks, like processing and invoicing, freeing up your team to focus more of their time on high-value activities. Additionally, consider installing things like sensors and smart devices to your warehouse, to receive real-time visibility into shipments, stock numbers, warehouse conditions, and more — helping you make faster and more informed decisions.

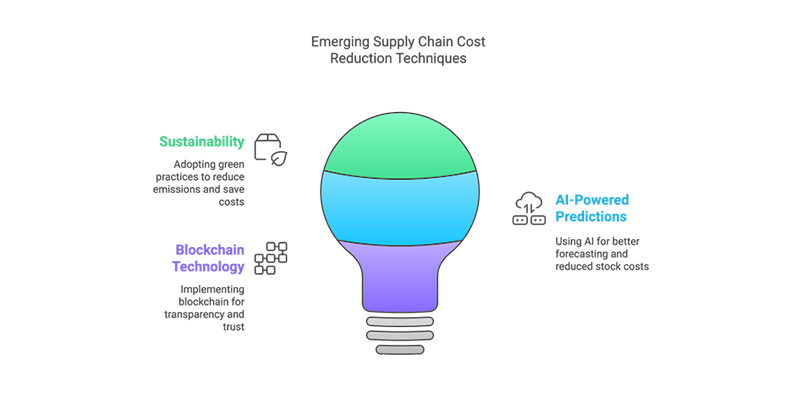

Emerging Supply Chain Cost Reduction Techniques

If you want to stay ahead of the competition, consider incorporating some of these additional supply chain cost reduction techniques into your strategy:

- Sustainability: Adopt green practices, such as utilising electric vehicles or optimising your delivery routes to reduce emissions while also saving money.

- AI-Powered Predictions: Use AI tools to improve forecasting — allowing you to streamline the procurement process and cut down on unnecessary stock, while also reducing warehouse cost if done correctly.

- Blockchain Technology: Implementing blockchain technology can improve transparency, reduce fraud, and increase trust amongst partners.

These emerging supply chain cost reduction techniques not only help reduce costs, but they can also improve efficiency, enhance customer satisfaction, and future-proof your processes. If you are able to address both immediate pain points and long-term trends, you can create a significantly more agile and competitive business.

Part of a Wider Business Health Check

While you are reviewing your supply chain, it is also a good idea to get an overview of other aspects of your business to ensure it is running as efficiently as possible. Perhaps you are thinking about growing your company but are unsure of the types of business funding sources that are available to you. You may even want to carry out an independent review of your firm to highlight any areas for improvement – such as cash flow management.

Whatever your business requirements, you can rely on Inquesta to help. We will carry out a thorough assessment of your business and recommend what we believe are the most appropriate solutions for you.

For more information, contact our team today or book a free consultation.

[/fusion_text][/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]